Preparing injectable compounds is a process that demands accuracy, consistency, and a solid understanding of the materials involved. Even minor errors during preparation can affect stability, safety, and effectiveness. Many of these issues stem not from negligence, but from confusion around terminology, improper assumptions, or lack of clear guidance. Understanding where mistakes commonly occur helps reduce risk and promotes better outcomes.

Misunderstanding the Purpose of Different Dilution Liquids

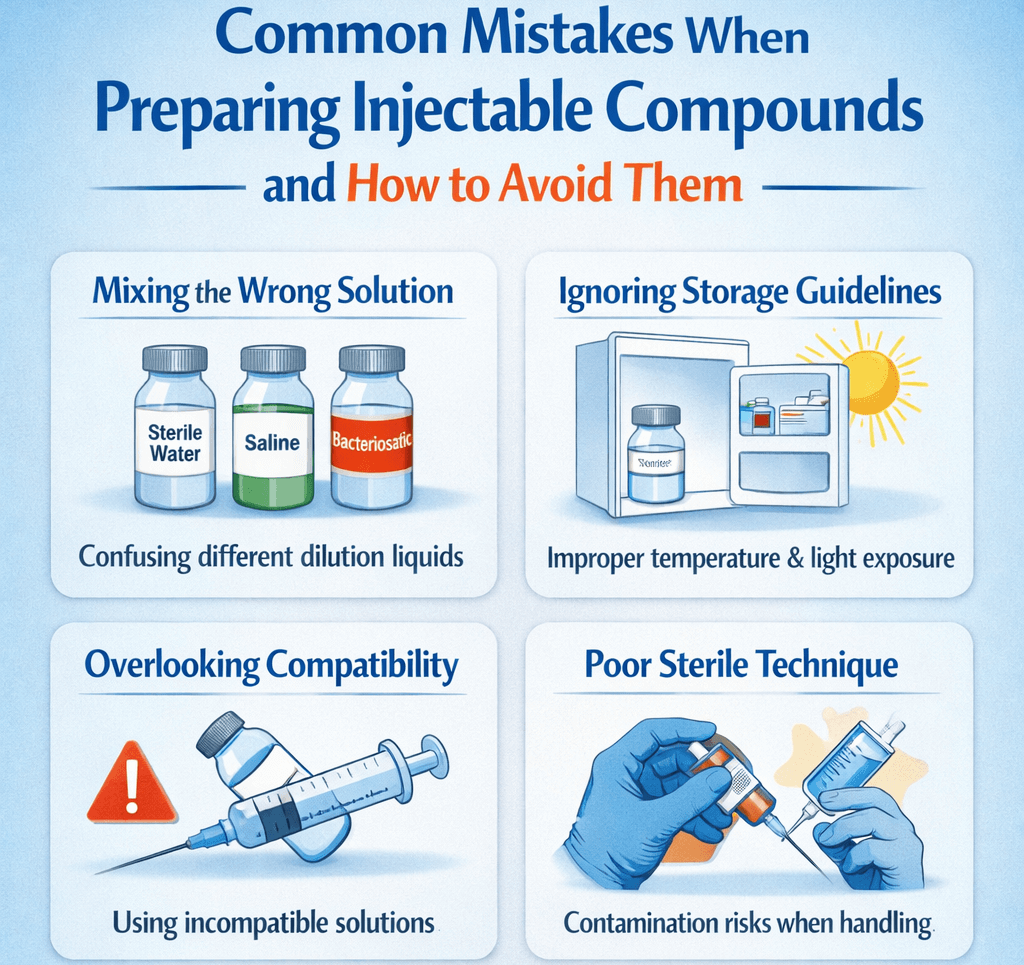

One of the most frequent problems arises from confusion between the liquids used to dilute or dissolve injectable compounds. Sterile water, saline solutions, and bacteriostatic water are often grouped together, even though they are designed for different purposes.

Each solution behaves differently once mixed with a compound. Some are intended strictly for single use, while others support multi-dose applications. Without understanding these distinctions, users may select a liquid that shortens shelf life or compromises sterility.

This confusion is why questions like is bacteriostatic water the same as reconstitution solution frequently surface. The misunderstanding usually lies in treating a general category as though it were a single product, when in reality, reconstitution solutions include multiple options with distinct properties.

Treating All Reconstitution Methods as Interchangeable

Another common mistake is assuming that if one compound dissolves well in a particular solution, the same approach will work universally. Injectable compounds vary widely in structure, sensitivity, and stability. What works for one formulation may be unsuitable for another.

Some compounds require preservative-free liquids to maintain integrity, while others tolerate or even benefit from bacteriostatic properties. Using a mismatched solution can lead to reduced potency, altered absorption, or accelerated degradation.

Understanding that reconstitution is not a one-size-fits-all process is essential for proper preparation.

Overlooking Storage Requirements After Mixing

Errors don’t stop once the compound is reconstituted. Improper storage is a major factor in reduced effectiveness and contamination. Temperature control, protection from light, and limiting repeated exposure to air all play a role in maintaining stability.

Multi-dose preparations are especially vulnerable. Each needle entry introduces a potential contamination risk if sterile technique is not strictly followed. Even when the correct solution is used, careless storage can render a preparation unusable long before its expected lifespan.

Knowing how long a compound remains viable after mixing is just as important as knowing how to mix it.

Ignoring Compatibility and Sensitivity Considerations

Certain applications require extra caution. Preservatives, for example, are not universally suitable and may be inappropriate in sensitive contexts. Failing to consider compatibility can result in irritation, adverse reactions, or reduced effectiveness.

The correct solution choice should always be guided by the compound’s requirements rather than convenience or availability. Skipping this step increases the likelihood of problems that could otherwise be avoided.

Relying on Assumptions Instead of Clear Information

Many preparation mistakes are repeated simply because they have become routine. Advice passed informally or practices copied without verification often lack important context. Over time, assumptions replace informed decision-making.

Taking the time to understand why specific solutions are used, how compounds behave once mixed, and what conditions affect stability leads to safer and more reliable results. Education plays a critical role in reducing preventable errors.

The Importance of Precision and Consistency

Precision is not just about measurements; it also applies to selecting the right materials and following consistent procedures. Even small deviations can compound over time, especially when preparing injectable solutions repeatedly.

Consistency in technique, storage, and handling builds reliability and minimizes risk. When preparation becomes a disciplined process rather than a habit-driven task, outcomes improve significantly.

Final Thoughts

Injectable compound preparation involves more than mixing powder and liquid. Understanding the differences between dilution solutions, recognizing compatibility requirements, and maintaining proper storage conditions all contribute to safety and effectiveness.

Avoiding common misconceptions and focusing on accurate, well-sourced information helps ensure that injectable preparations perform as intended. Attention to detail at every stage of the process remains the most reliable way to prevent errors.